What is a Non Return Valve

A Non Return Valve (NRV), also known as a check valve, is a mechanical device designed to allow fluid or gas to flow in one direction while preventing backflow. It ensures system safety, efficiency, and reliability by maintaining unidirectional flow in pipelines, pumps, and industrial systems.

Non Return Valve Structure

Non Return Valves feature a simple yet effective design. Key components include:

Valve Body: Houses internal parts and connects to the pipeline.

Disc or Flap: Moves freely to open or close the flow path.

Spring (optional): Enhances closing force in spring-loaded designs.

Hinge or Pivot: Allows the disc to swing or lift.

Seat: Ensures a tight seal when the valve closes.

This robust structure minimizes pressure loss while maximizing durability.

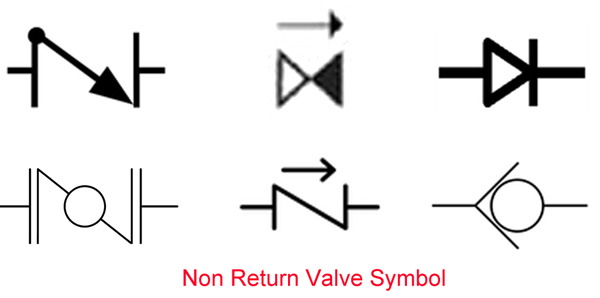

Non Return Valve Symbol

In engineering schematics, the Non Return Valve symbol is represented by a triangle pointing in the flow direction with a diagonal line or a curved arrow indicating one-way operation. This standardized symbol helps engineers quickly identify valve placement in piping and instrumentation diagrams (P&ID).

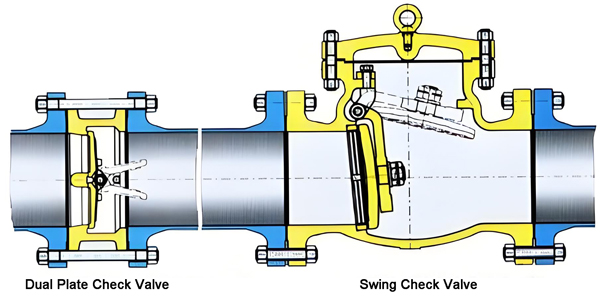

Non Return Valve Types

Non Return Valves come in multiple designs for diverse applications:

Swing Check Valve: Uses a hinged disc for low-pressure systems.

Lift Check Valve: Employs a piston-like disc for vertical flow.

Ball Check Valve: Utilizes a ball to block reverse flow.

Dual Plate Check Valve: Compact design for high-pressure systems.

Wafer Check Valve: Lightweight and ideal for limited-space installations.

C95800 Check Valve: Material in Bronze C95800, and valve type in Dual Plate and Swing Type.

Non Return Valve Applications

Non Return Valves are critical in industries such as:

Water Treatment: Preventing backflow in pumps and filtration systems.

Oil & Gas: Protecting pipelines from reverse flow in refineries.

HVAC: Maintaining airflow direction in heating/cooling systems.

Chemical Processing: Safeguarding against hazardous fluid reversal.

Pharmaceuticals: Ensuring sterile, unidirectional fluid transfer.

Non Return Valve Advantages

Prevents Backflow: Protects equipment from damage caused by reverse flow.

Low Maintenance: Simple design reduces wear and operational costs.

Versatility: Compatible with liquids, gases, and high-temperature media.

Energy Efficiency: Minimizes pressure drop for optimized system performance.

Why Choose a Non Return Valve

Selecting a high-quality Non Return Valve ensures system longevity and safety. Partner with reputable Non Return Valve Manufacturers and Suppliers, especially those in China, known for cost-effective and durable solutions. China Non Return Valve Factories adhere to international standards, offering customized valves for specific industrial needs.

Post time: Apr-11-2025